Cikakkun Palletizer Na atomatik

Sigar fasaha

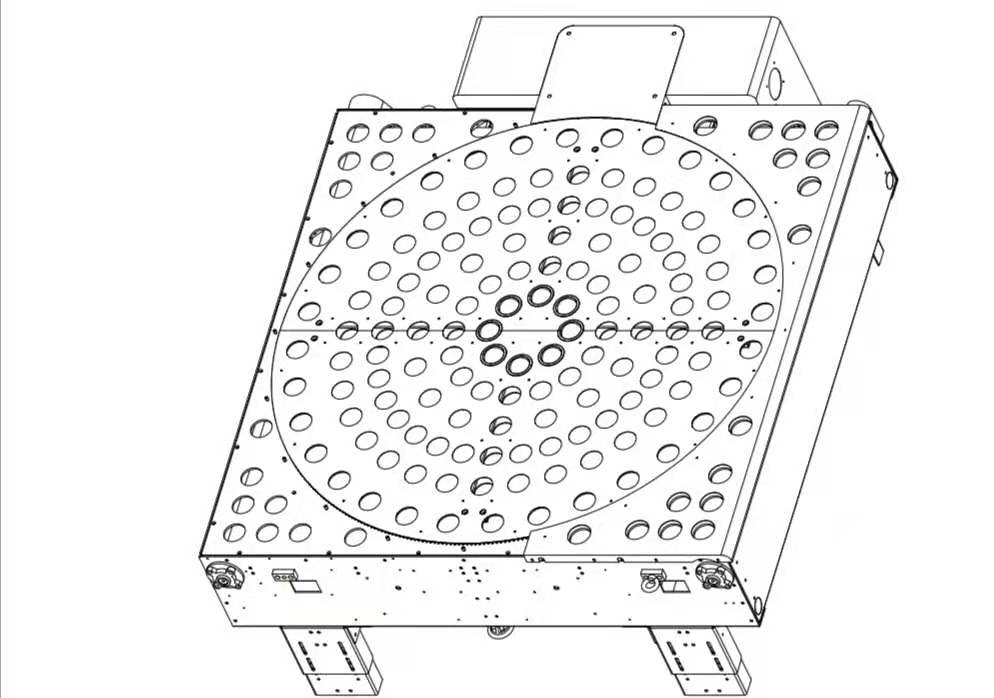

| Samfura | Saukewa: SC-1800MD |

| Girman inji (L*W*H) | 14290mm*5000*3500mm |

| Ƙare girman samfurin bayan tari | Max: 1700mm*1700*1800mm |

| Min: 800mm*800*1800mm | |

| Girman daure guda ɗaya | Max: 1700mm*1700*250mm |

| Minti: 300mm*300*50mm | |

| Girman takarda guda ɗaya | Minti: 1500mm*1500mm |

| Minti: 600mm*600mm | |

| Girman pallet | Max: 1500mm*1500*150mm |

| Min: 1000mm*800*150mm | |

| Single Layer Max load | 15KG |

| Matsakaicin nauyin pallet guda ɗaya | 180KG |

| Saurin ɗagawa | 4 yadudduka/minti (Lura: iyaka gudun) |

| Saurin sakawa juyi | 10 daure/minti (Lura: tazara tsakanin kowane nau'in ya fi 6 seconds) |

| Ƙarfi | 15KW |

| Nauyi | 9T |

| Bayani: Matsakaicin matsakaici da mafi ƙarancin girman samfurin palletizing basu haɗa da tsayin mai isar ƙasa ba.Tsawon isar da ƙasa shine: 350mm±10 mm, kuma gudun shine: 20m/min. | |

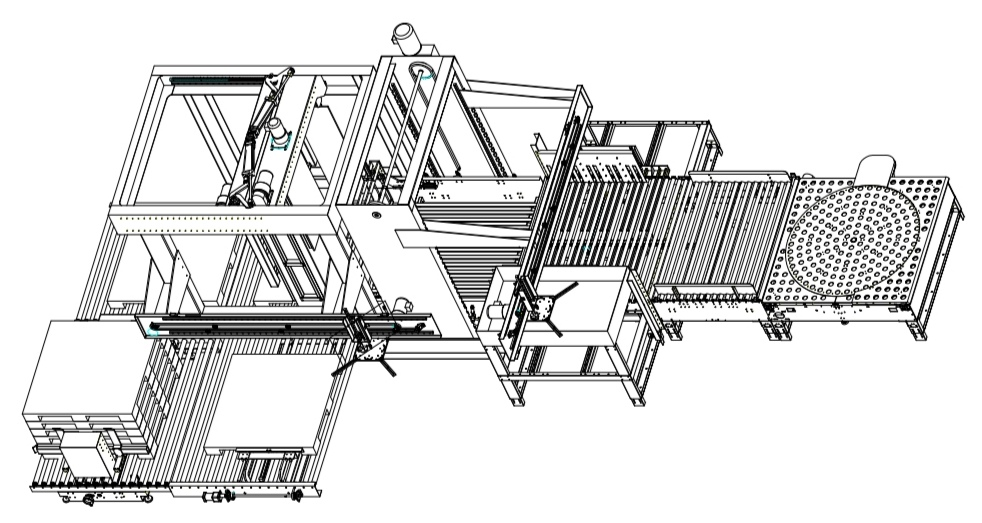

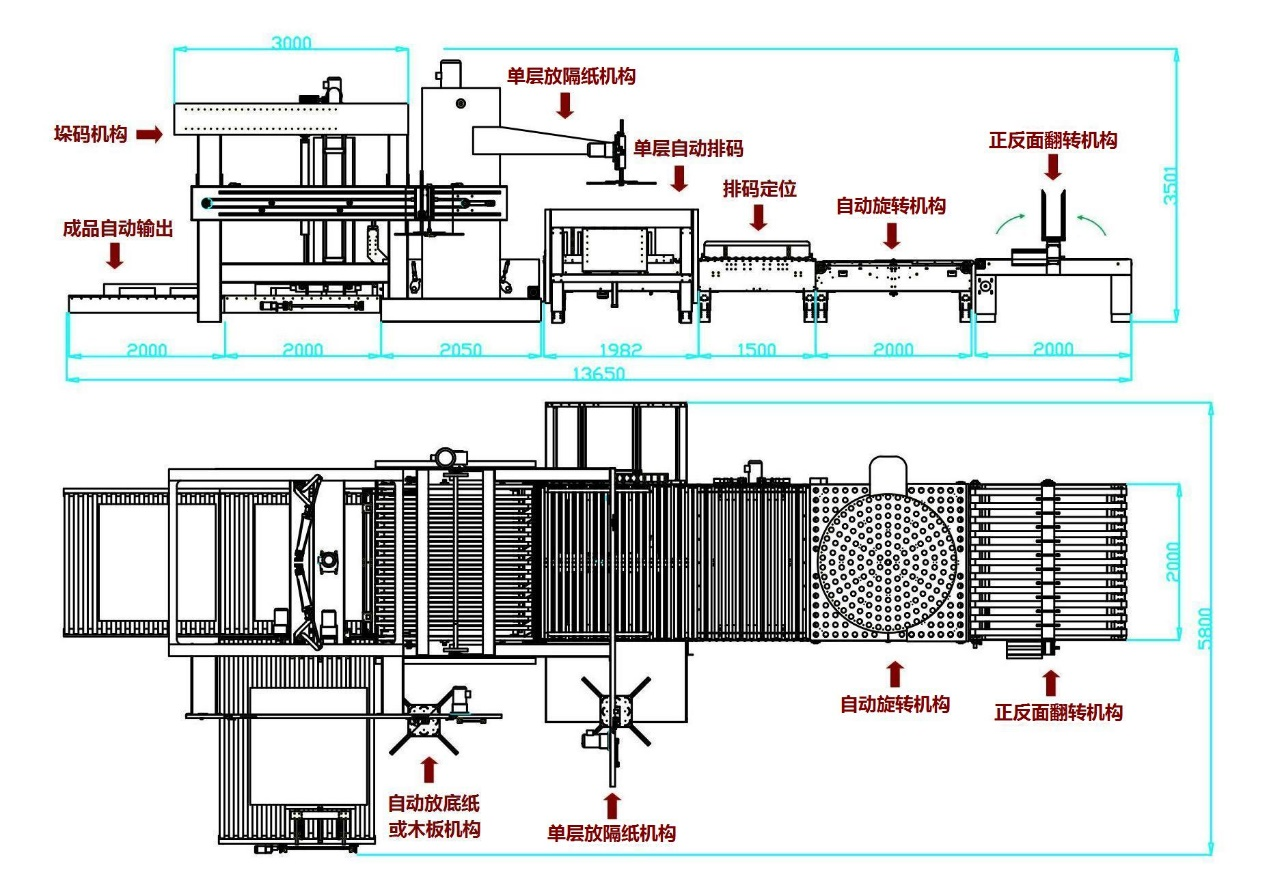

Bangaren:

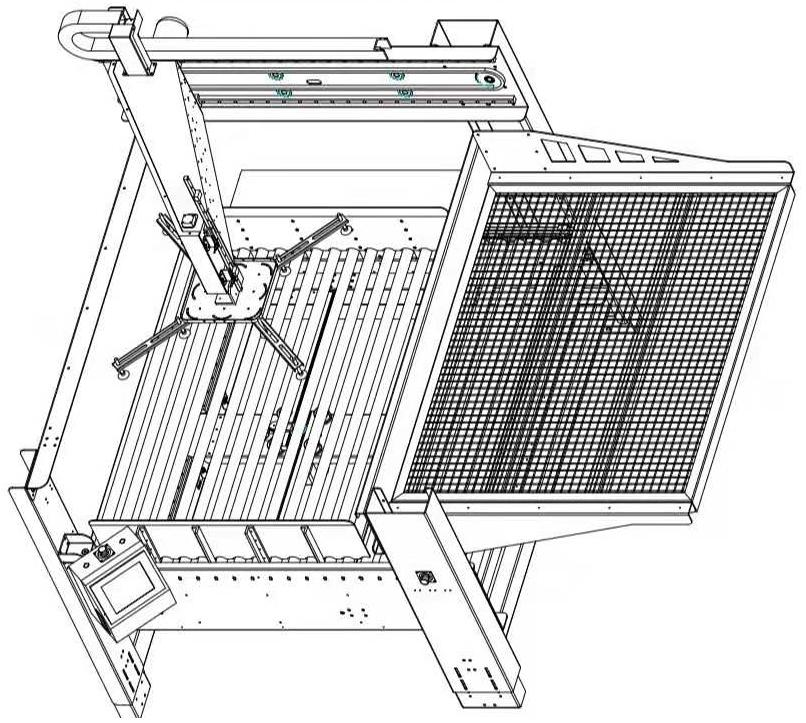

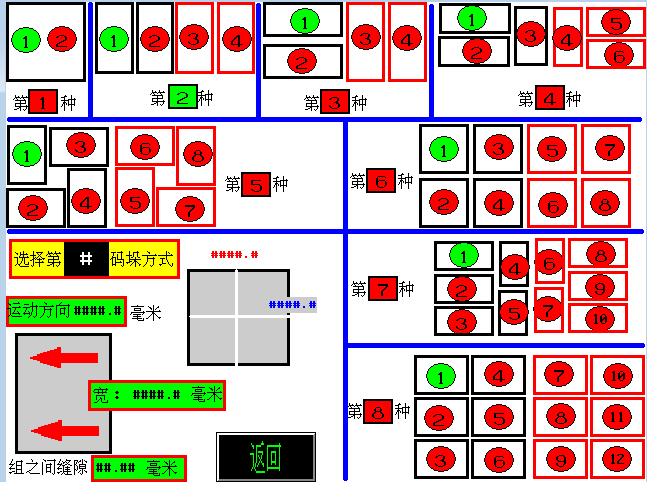

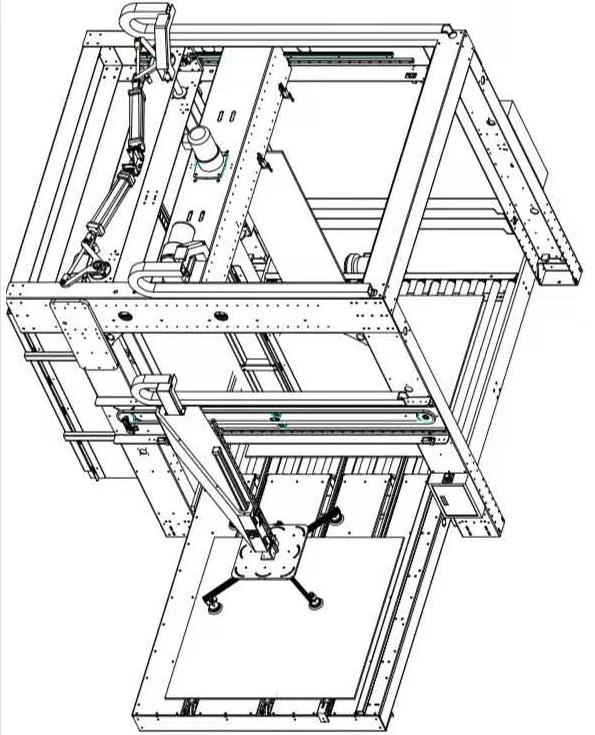

Tsarin juyawa na gaba da baya (sayan zaɓi): Dangane da buƙatun tarawa, yanayin juyawa na gaba da baya an zaɓi shi ta hanyar saitin PLC (juye gaba da baya don kowane tari ko tari), kuma ana sarrafa zaɓaɓɓun gefen gaba da baya. ta mai rabo.

Rotator ta atomatik:

Dangane da buƙatar palletizing, jagora ko kusurwar da za a juya an saita shi a cikin tsarin sarrafawa, kuma ana sarrafa injin tuƙi ta hanyar servo motor don kammala aikin juyawa a cikin hawan keke.

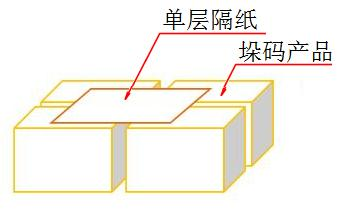

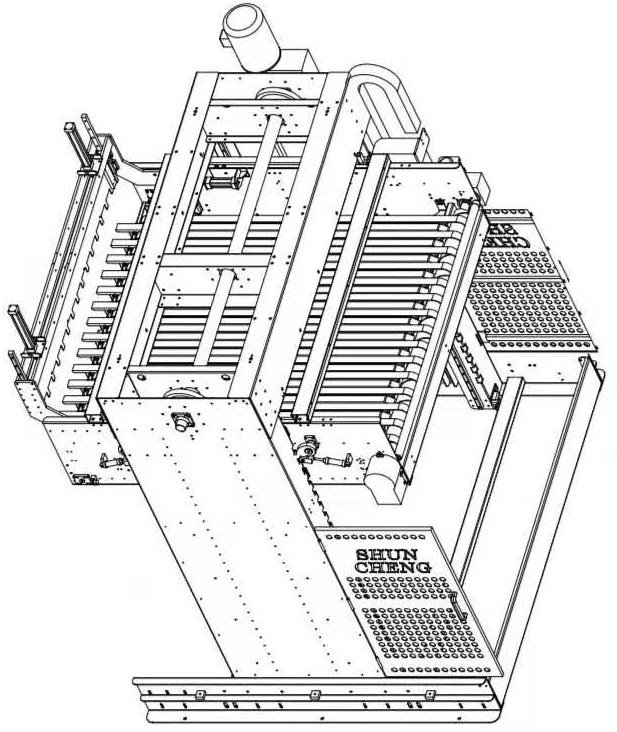

∎ Sanya kayan aiki da stacking mai Layer guda:

An saita samfuran palletizing ɗin da aka juya baya kafin da kuma bayan buƙatun palletizing, sannan ana cire tsari ta atomatik daga hanyar palletizing guda ɗaya, kuma a lokaci guda, za'a iya saita interlayer don sanya takarda ta atomatik ta atomatik.

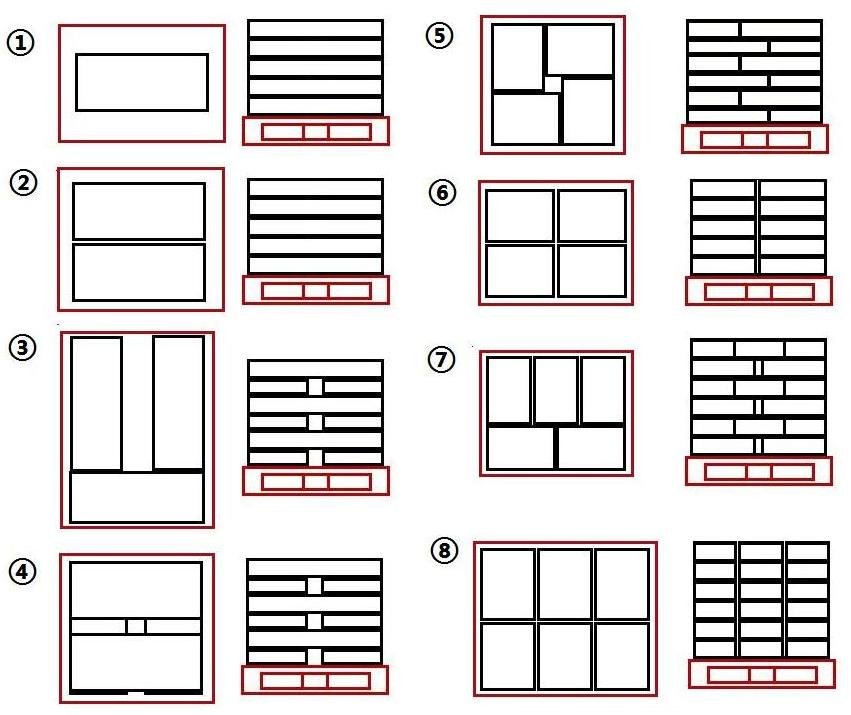

Dace da hanyar palletizing:

■Dagawa mai ɗagawa guda ɗaya da palletizing palletizing:

Ana aika samfuran Layer Layer bayan palletized zuwa injin ɗagawa ta atomatik.Bayan injin ɗagawa na ɗagawa ya tashi zuwa wani tsayin faifan pallet ɗin, samfuran palletizing ɗin mai Layer guda ɗaya ana turawa zuwa pallet ɗin don kammala pallet ɗin, sa'an nan kuma ana ɗaga pallet ɗin zuwa Layer na gaba na tsayin stacking don madauwari ta atomatik.Lokacin da pallet ya kai tsayin da aka kayyade, ana fitar da duka tari ta atomatik, kuma a lokaci guda, ana ba da pallet ta atomatik ta injin ciyar da pallet ta atomatik don aikin palleting na gaba.

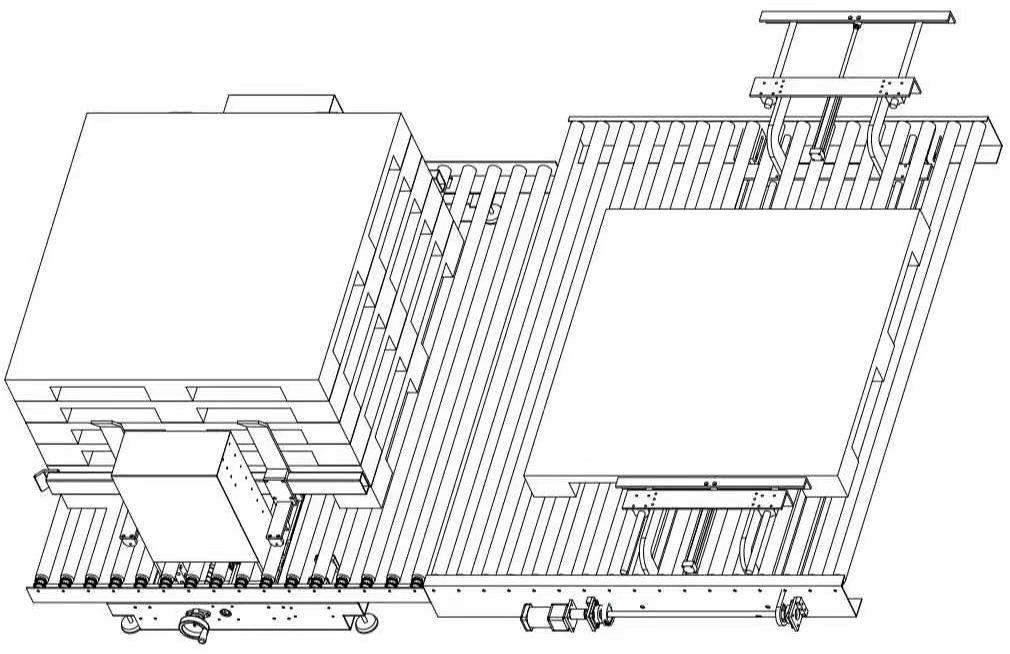

■ Naúrar sake cikawa ta atomatik:

An kasu kashi na palette: yankin allon da aka riga aka tattara da kuma na'ura mai cike da pallet ta atomatik.Lokacin da naúrar atomatik na pallet ɗin ya cika da pallet ɗin da ake buƙatar sake cikawa, ana iya tara pallets ɗin da ake buƙatar sake cikawa da hannu ko ta hanyar cokali mai yatsa a cikin wurin da aka riga aka tara;Hanyar tarawa ta dogara ne akan ƙayyadadden matsayi na faifan pallet Stacking Stacking, lokacin da pallet stacker ya tattara dukkan pallet bisa ga buƙatu kuma ta fitar da shi ta atomatik, pallet ɗin da ke jiran wurin cikawa ana jigilar shi ta atomatik zuwa wurin da aka keɓance na palletizer stacking. samfurin, kuma na'urar gyaran gyare-gyare ta atomatik ta fara sake cika pallet Je zuwa matsayi na pallet a cikin wurin da ake jira da jira kuma jira na gaba mai cike da pallet;lokacin da aka yi amfani da na'ura mai cike da pallet ta atomatik, yankin pallet pre-queue yana farawa tare da ɗimbin ɗimbin palette kuma ana jigilar shi kai tsaye zuwa pallet Sashin gyaran allo yana jira don sakewa.

Alamar bayanin manyan abubuwa

| Suna | Alamar | Suna | Brad |

| Mai rage motsi | Taiwan Shengang | PLC | FATEK |

| Inverter | Panasonic | Mai tuntuɓar juna | Shilin Taiwan |

| Kariyar tabawa | Taiwan Hitech | Maɓallin kariya ta thermal | Simens, Jamus |

| Silinda iska | Taiwan Air TAC | Relay | Idec, Japan |

| Babban tasiri | NSK, Jan | Canjin wuta | Mitsubishi |

| Servo motot | Yaskawa | Mai aiki tare | Omron |

| Sarrafa Servo | FATEK | Laser ido | Panasonic |

| Photoelectric canza | Panasonic | Allon bango na inji | 5mm lokacin farin ciki lankwasawa farantin, 150mm * 150mm murabba'in |

| Madaidaicin Slide | Taiwan Hiwin | Electromagnetic bawul | Farashin TAC |

| Maɓalli | Schneider | Photoelectric Eye | Panasonic |